The first stage in the manufacture of garments

is the cutting of the materials into the necessary pattern shapes. These are

then joined by means of seams to create 3D garments. When a single garment is cut out,

the garment pattern is attached to 1 or 2 plies of the fabric. The garment

parts are then cut out with hand sheers. Where large quantities of a garment

style must be cut, a lay is created which consists of many plies of fabric

spread one above the other. From this must then be cut all the garment pieces

for all the sizes which it has been planned to cut from that lay.

# Processes of cutting room

- Planning, drawing & reproduction of the marker

- The spreading of the fabric to form a lay

- The cutting of the fabric

Planning, drawing & reproduction of the marker:-

The industry has always paid great

attention to marker planning, because when the cutting

room cuts cloth it spends around half the company’s turnover; any reduction in

the amount of cloth used per garment leads to increased profit. Marker planning is a

conceptualising, intuitive, open and creative process. There is no final

solution to a marker planning problem, only a more tightly packed and therefore

shorter marker. The work of marker planning is subject to a number of

constraints, that is:

1. The

nature of the fabric and the desired result in the finished garment- this includes pattern alignment in

relation to the grain of the fabric, symmetry of the pattern/ construction of

the fabric, the design characteristics of the finished garment.

2. The

requirement of quality in cutting- the placement of the pattern pieces in the marker

must give freedom of knife movement, a pattern count must always be maintained

and there should be correct labelling of cut garment parts.

3. The

requirements of production planning-

Marker mode: is the classification of markers based on the direction in which the

pattern pieces are placed on the fabrics or marker. The main criteria which

influences the choice of the marker mode is the grain of the pattern and the

nature of the fabric, as discussed above. The efficiency of the marker, i.e. the success of the marker, is

greatly affected by the marker mode chosen. This is greatly subjective to the

combination of the spreading mode and the marker mode, for the same fabric or

garments. One spreading mode might prove to be more efficient than the other,

for the same marker mode chosen.

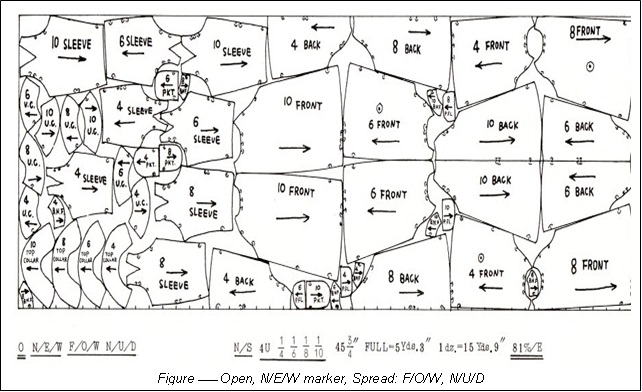

Marker

modes are characterised by whether they are open

markers, all pattern pieces are placed open on the flat fabric, or closed markers, the fabric and patterns

are on fold. Another important consideration in the nomenclature of the marker

mode is the nap or direction in which

the pattern pieces are placed on the marker. This is denoted as Nap One Way (N/O/W), Nap Either Way (N/E/W)

and Nap Up & Down (N/U/D).

|

| Nap Either Way Marker |

|

| Nap One Way Marker |

|

| Nap Up & Down Marker |

1. Open,

Nap One Way (N/O/W) marker – This marker mode consists of all the pattern

pieces facing in one direction, towards top generally. It’s common with

asymmetric fabrics or directional prints, where direction of the nap or the

print face an important feature in the garment. The open, N/O/W marker uses

F/O/W, N/O/W spreading mode for highest quality. However, the speed of this

spreading mode is slower and the marker layout is less economical.

2. Open,

Nap Either Way (N/E/W) marker – As the name suggests this marker is made on

an open width of the fabric. The pattern pieces composing this marker are

placed in either direction, without compromising on the grain line marked on

the pattern, i.e. the straight grain pattern piece could either face the top

direction or the bottom direction even within the same size. This type of

marker is possible with symmetrical fabrics only, which can be spread fast in

F/O/W, N/U/D mode. However, the quality and the efficiency of the marker are

medium.

3. Closed,

Nap One Way (N/O/W) marker – This marker is planned for folded or tubular

fabrics, hence the name closed. The spreading mode used in such a case would be

Face to Face, Nap One Way (F/F, N/O/W), which nonetheless is a slow process.

The resultant marker is of a medium quality and low in efficiency (<80%).

4.

Closed,

Nap Up & Down (N/U/D) – As in the previous method, this

marker is used on folded or tubular fabrics spread F/F, N/O/W. However all the

pattern pieces corresponding to one size will face in one direction and that

for the other size will face in the opposite direction, without changing the

grain-line of the pattern. This method proves to have medium to low efficiency

and quality, depending on the sizes combined together.

5.

Closed,

Nap Either Way (N/E/W) – Low quality but high efficiency can be

achieved by laying the patterns facing in either direction on a folded or

tubular fabric that is spread in F/F, N/U/D mode.

Marker Making Parameters -

- Wider the width of the fabric, better consumption.

- Arrange bigger patterns first.

- Open width of knits gives the better consumption for maximum styles.

- Effective width is width (or area) that can really be used without the selvedge.

- Grain line marked on the pattern should always be followed.

- Table length is limitation.

- Follow pattern checklist, to maintain a pattern count of total pattern pieces placed as opposed to total number of pattern pieces.

- Colour variation to be considered while sorting fabric rolls. Centre- selvedge colour variation, selvedge – selvedge colour variation. Pattern arrangement to depend on colour variations, if any.

- Keeping in mind roll length available we can calculate effectively the lay length for more effective utilisation of fabrics.

- Block cutting is followed for embroidery purpose, and for check matching.

- Cutting cuffs lengthwise on fold gives max utilisation.

- Fabric type decides marker mode.

- Extra area is created at pattern edges based on stickering or stamping procedure to be followed.

- Enlarged pattern blocks in marker for embroidery.

- Cutting equipment influences the space between patterns.

Computerised Marker Making

This method is normally part of an

integrated system which includes digitising or scanning of full-size patterns

into the computer, facilities for pattern adaptation, and, by inputting

appropriate grade rules, the means to generate all the sizes required. The

planner uses a visual display unit with keyboard, tablet and data pen, puck or

mouse.

Methods and equipment vary slightly between manufacturers but a typical

example is as follows. The planner specifies the exact make-up of the marker

plan: the width of the fabric, the pattern pieces to be used, the sizes to be

included and all constraints to be applied, including any matching of checks.

The system produces a marker plan automatically or interactively. Automatic

marker planning involves calling up data defining from a series, that marker

conformation which gives the highest marker efficiency. There is no guarantee

that the best marker plan will be achieved, but this is rapid method of

achieving a relatively efficient plan and it had the advantage of not needing

an operator.

Interactive marker planning is more common and is the process by which

the operator plans markers by interacting directly with the system through a

VDU screen. All the pattern pieces are displayed in miniature at the top of the

screen. In the middle of the screen are two horizontal lines defining the

marker width and a vertical line at the left representing the beginning of the

marker. The right end is for the moment open. At the bottom of the screen is a

written marker identification, with marker length and efficiency constantly

updated during the planning process.

A data pen (or puck or mouse), tablet and the computer keyboard are used

to manipulate the pattern pieces. The tablet, which rests on the desk in front

of the operator, represents the display screen and consists of a grid of fine

wires immediately below the surface. When using a data pen, the pen is touched

on the surface of the tablet and it registers a position on the grid which

shows as a position on the screen. A combination of movements of the pen and

commands via the keyboard enable pattern pieces to be moved about the screen

and positioned in the marker. The system finally positions the pattern pieces

precisely according to the marking rules specified. This process enables the

planner to produce a trial marker very rapidly and accurately, thus enabling

the planner to run through the feasible placements of pattern pieces more

quickly than with non-computerised systems. After selecting the most economical

marker plan devised in the time available, the computer will provide an

accurate piece count, calculate a marker plan efficiency percentage and total

the length of the pattern peripheries. When the marker plan is complete, it

will be stored in a marker plan file for future retrieval. The system is not

limited to large marker plans but can be used, when combined with a pattern

adaptation facility, to provide single size marker plans for made-to-measure

cutting of men’s suits.

An alternative to the data pen in some systems is the puck or mouse. In

this case keys are pressed to achieve the same effect as pressing the data pen

on the tablet.

The quality of marker planning is more consistent that with manual

methods, because instructions regarding grain lines are always followed,

because the butting of pattern pieces is precise with no overlapping, and the

pattern count is automatic, a boon in complex markers.

Commonly available apparel pattern making, marker making and grading

software’s include those by Lectra, Tukatech, REACH Technology, Nester, Gerber

Technology, CISMA, BERNINA, OptiTex etc.

Comments

Post a Comment